Manufacturing Application-Driven Foveated Near-Eye Displays

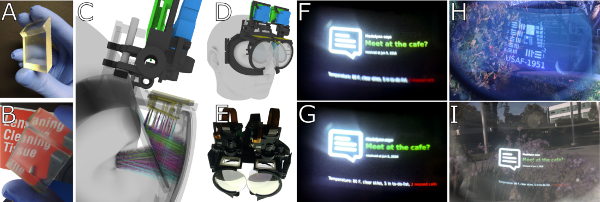

Traditional optical manufacturing poses a great challenge to near-eye display designers due to large lead times in the order of multiple weeks, limiting the abilities of optical designers to iterate fast and explore beyond conventional designs. We present a complete near-eye display manufacturing pipeline with a day lead time using commodity hardware. Our novel manufacturing pipeline consists of several innovations including a rapid production technique to improve surface of a 3D printed component to optical quality suitable for near-eye display application, a computational design methodology using machine learning and ray tracing to create freeform static projection screen surfaces for near-eye displays that can represent arbitrary focal surfaces, and a custom projection lens design that distributes pixels non-uniformly for a foveated near-eye display hardware design candidate. We have demonstrated untethered augmented reality near-eye display prototypes to assess success of our technique, and show that a ski-goggles form factor, a large monocular field of view (30o×55o), and a resolution of12cycles per degree can be achieved.

Publication Date

Research Area

External Links

Uploaded Files

Copyright

This material is posted here with permission of the IEEE. Internal or personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional purposes or for creating new collective works for resale or redistribution must be obtained from the IEEE by writing to pubs-permissions@ieee.org.